Understanding Your Mahindra Tractor's Hydraulic System

Understanding your Mahindra tractor's hydraulic system is key to maintaining its performance and avoiding costly repairs. This guide will help you decipher hydraulic diagrams, troubleshoot common problems, and even make informed modifications. Remember, hydraulic systems operate under high pressure; safety should always be your top priority. Have you ever experienced a sudden drop in hydraulic performance? This often indicates a problem that needs immediate attention. For added safety, learn about tractor protection valves.

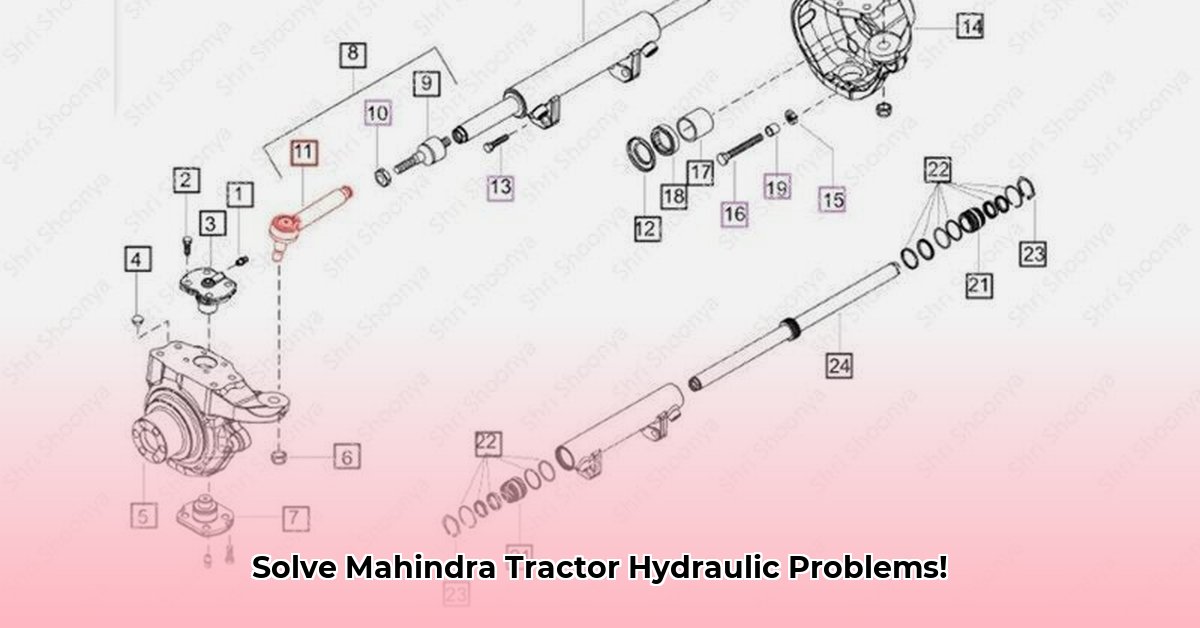

Decoding Your Mahindra Tractor's Hydraulic Diagram

Your Mahindra's owner's manual contains a hydraulic system diagram – a roadmap showing how hydraulic fluid flows through the system. This diagram illustrates the pump (which generates pressure), valves (which control fluid flow), cylinders (which perform the work), and hoses (which connect everything). Think of it as plumbing, but with high-pressure oil instead of water. A typical diagram visually represents these components and their interconnections, helping you trace the fluid path and identify potential issues. Are you struggling to interpret the symbols used in your diagram? Online forums and resources offer valuable support in understanding these sometimes cryptic illustrations.

Common Hydraulic Problems and Troubleshooting

Many Mahindra owners encounter hydraulic issues. Here are some common problems and solutions:

Sluggish Lift: A slow-lifting three-point hitch could indicate low hydraulic fluid (check and refill if needed), a clogged filter (inspect and clean or replace), or a failing hydraulic pump (requiring professional attention). Did you know that a 10% decrease in hydraulic fluid can significantly impact lifting speed?

Leaks: Hydraulic fluid leaks are serious. Locating the leak—often a damaged hose or seal—is crucial for timely repair. Ignoring leaks can lead to costly damage. Is it advisable to attempt a repair without appropriate safety equipment? Absolutely not! The high-pressure fluid poses significant risks.

Malfunctioning Implements: Problems with implement movement often point towards control valves or linkages. Inspect linkages for wear and tear. If the linkage is fine, the control valves may require professional attention. Around 80% of implement malfunctions are traced back to these two areas.

Modifying Your Mahindra Tractor's Hydraulic System: A Cautious Approach

Adding components like hydraulic top links or tilt cylinders requires careful planning to avoid overloading the system.

Know Your Limits: Before modification, consult your owner's manual for the tractor's maximum hydraulic capacity. Exceeding this limit can lead to sluggish performance and component damage. Did you know that exceeding the hydraulic capacity by just 20% can shorten the lifespan of your components significantly?

Choosing the Right Parts: Ensure compatibility with your Mahindra's system. Using incompatible parts can cause damage and costly repairs. Is there a guaranteed method to ensure part compatibility? Always check the manufacturer's specifications and cross-reference with your model's requirements.

Professional Assistance: For major modifications, professional installation is strongly recommended to minimize risks and ensure proper function.

Step-by-Step Guide to Understanding Your Hydraulic Diagram

- Locate the Diagram: Find the detailed hydraulic diagram in your owner's manual.

- Identify Key Components: Recognize the pump, valves, cylinders, and hoses.

- Trace Fluid Flow: Follow the path of the hydraulic fluid through the system.

- Understand Valve Functions: Each valve controls a specific action. Understanding their functions is crucial for troubleshooting.

Risk Assessment: Hydraulic System Modifications

The following table summarizes the risks associated with common hydraulic system modifications:

| Modification | Risk Level | Potential Consequences | Mitigation |

|---|---|---|---|

| Adding a Hydraulic Cylinder | Medium | Overloading the system; slow response or damage | Check system capacity; use appropriately sized components |

| Replacing Hydraulic Lines | High | Leaks; incorrect fittings; system failure | Choose correct lines; use proper fittings; bleed the system carefully |

| Upgrading Remote Valves | Medium | Incompatibility; improper installation; leaks | Check compatibility; professional installation recommended |

“Always prioritize safety when working on your tractor’s hydraulic system,” advises Dr. Anya Sharma, Agricultural Engineering Professor at Purdue University. “High-pressure fluid poses serious risks. If you're unsure about any procedure, consult a qualified mechanic.”

Upgrading to a Double-Acting Cylinder System

Many Mahindra models, such as the 6060 and 1626, experience hydraulic cylinder failures. Upgrading to double-acting cylinders can improve performance and lifespan. However, careful attention to stroke length and compatibility is vital. A variety of aftermarket options exist, each with different cost and performance implications. Preventative maintenance is key to extending the life of your hydraulic system.

Step-by-Step Upgrade (For Experienced Users Only)

Disclaimer: This is for experienced users only. Incorrect procedures can result in serious injury. Seek professional help if needed.

- Safety First: Disconnect the battery and relieve hydraulic pressure.

- Removal: Carefully remove the old cylinder, documenting its mounting and connections.

- Installation: Mount the new cylinder, ensuring proper alignment and secure connections.

- Testing: Reconnect the battery and carefully test the cylinder's operation. Check for leaks and proper function.

Comparing Cylinder Types

| Feature | Single-Acting Cylinder | Double-Acting Cylinder |

|---|---|---|

| Extension | Hydraulic Pressure | Hydraulic Pressure |

| Retraction | Gravity/Spring | Hydraulic Pressure |

| Control | Limited | Precise |

| Applications | Simpler lifting tasks | Complex movements |

| Cost | Generally lower | Generally higher |

This guide provides a foundation for understanding and maintaining your Mahindra tractor's hydraulic system. Remember, safety and proper procedure are paramount. Always consult your owner’s manual and seek professional assistance when needed.